Water is a critical component for humans and business operations. How to save it?

In this blog you will learn about the water related challenges, and how Food and Beverage, OEM, Food retail , Institutional and Agricultural industries can save water.

One of the issues that we face in today’s world is water scarcity. Water is a critical component for humans and business operations, therefore if every individual and factory could change its behavior, take responsibility for its action, and save water, it would make a huge difference.

What are the water-related challenges?

According to UN, there are nine water- related challenges, some of which are:

- 2.2 billion people lack access to safely managed drinking water services.

- Almost 2 billion people depend on health care facilities without basic water services.

- Over half of the global population or 4.2 billion people lack safely managed sanitation services.

Goal 6 of the UN’s Sustainable Development Goals is ensuring availability and sustainable management of water and sanitation for all. “The goal is ambitious, but it is not a rocket science”. If every household, and factory could change its behavior, take responsibility for its action, and save water, it would make a difference.

How does Nilfisk FOOD cleaning equipment help to save water and contribute to sustainable efforts?

Nilfisk FOOD engineers cleaning and hygiene solutions that optimize cleaning processes and food safety around the world, helping food and beverage producers, OEMs, Food Retail industry, Institutional industry to focus entirely on what they are best at. Nilfisk FOOD cleaning equipment delivers the best technically possible hygienic results, while supporting sustainable efforts of saving water, energy and detergents used for cleaning.

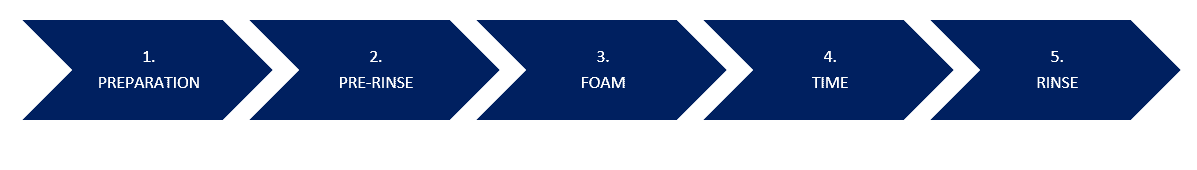

Do you know that during the entire cleaning process consisting of ten steps (See figure 1) , the Pre-Rinse and Rinse steps take most of the cleaning time and consume the most water?

Fig.1 – Order of cleaning food contact surface to achieve maximum hygiene results and food safety

Nilfisk FOOD spent therefore a lot of research on developing technologies to save water specifically when rinsing with clean water. As a result, our patented technologies help to safe up to 47% of water usage, reduce energy consumption, reduce greenhouse gas emissions and CO2 emissions.

To dissolve fats effectively, hot water is used for cleaning, which consumes energy (electricity or natural gas). Optimizing water use will result in reducing energy consumption, and in turn, indirectly help reduce greenhouse gas emissions and CO2 emissions.

Consuming less water will create less wastewater that need to be processed to make it safe again, thus it will also reduce energy and reduce the greenhouse gas emissions.

Have a look at concrete examples of what impact the water savings make at the customers using Nilfisk FOOD cleaning equipment.

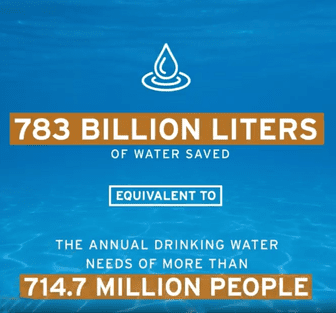

One of our partners Ecolab provides innovative programs and solutions that help customers reduce, reuse, and recycle water. Surface cleaning/ Clean out of Place method with foam cleaning program supplied by Nilfisk FOOD is one of the methods. Each method and technology contribute to saving water, and all solutions together contributes to overall savings of 783 billion liters of water annually (2021) which is equivalent to the annual drinking water needs of more than 714,7 million people.

Another more concrete example is from a Fish producer Sofrimar.

Centralized cleaning equipment from Nilfisk FOOD was installed at Sofrimar, contributing to significant savings on water. The water flows were reduced from100L/minute to 30-40L/minute and afterwards based on positive feedback, were reduced further to 20-30L/minute. Besides saving water, Sofrimar also experience easier and quicker cleaning process, reduced chemical usage and reduced misting throughout the site which improved the efficiency of the final rinse step.

The payback on the investment was generated during less than 2 years.

Investment: €34,000

Annual saving: €20,000

Read the whole case study fromSofrimar in here

Would you like to receive the best technically possible hygienic results, and contribute to sustainable efforts of saving water, energy and detergents while cleaning? Book a 30-minute, free of charge consultancy session with our experts so we can discuss how Nilfisk FOOD can help with that.