Low pressure vs. High pressure Cleaning

Many hygienic teams, all over the world, have their own outlook on the century long question “which pressure – High or Low – works best when cleaning in the food industry?” what are your thoughts?

Common Myth

Although the standard of cleaning is different all over the world within the food industry, there are parts of the world that are still sure that if they have a high pressure system then it must clean better. Surprise, that is not the case! – especially in the food industry. Do you also believe high pressure gives a higher quality of cleaning?

Well, that myth has already been busted by a third party technological institute*. They conducted four different tests on the low & high pressure systems.

Below we are comparing four scenarios:

- Loss of temperature

- Impact (Pressure against surface)

- Aerosols

- Cleaning efficiency

Before we can get to the results we will go over the capacities tested:

Capacity

Capacity is the water flow rates ability to remove gross soil. The larger the capacity the faster the soil is removed from the surface.

| Water Flow Rates l/min (gallon/min) | Working Pressure Bar(psi) | Nozzle Type/Size (gal/min) |

| High Pressure (HP) 21 l/min. (5.5 gallon/min) | 60-85 (870-1232) | ¼” MEG 25/12 (25/3.2 gal/min) ¼” MEG 25/10 (25/2.64 gal/min) |

| Low Pressure (LP) 5-100 l/min. (1.3-26 gallon/min) | 25 (362) | ¼” VEEJET 25/40 (25/10.6 gal/min) ¼” VEEJET 15/30 (15/8 gal/min) |

| System | Nozzle Type Angle/Capacity (angle/gal/min) | Working pressure Bar (psi) | Capacity I/min (gal/min) |

| LP | 25/40 (25/10.6) | 22 (319) | 35,4 (9.4) |

| LP | 15/30 (15/8) | 22 (319) | 28,8 (7.6) |

| HP | 25/12 (25/3.2) | 60 (870) | 18,7 (4.9) |

| HP | 25/10 (25/2.64) | 85 (1232) | 18,8 (5) |

| Capacity Test results | Low pressure (22 bar/319 psi) has the highest capacity with 35,4 liters per minute (9.4 gal/min). The capacity when using high pressure (60 bar & 85 bar/870psi & 1232psi ) is 18,7 & 18,8 liters per minute ( 4.9 & 5 gal/min) accordingly. |

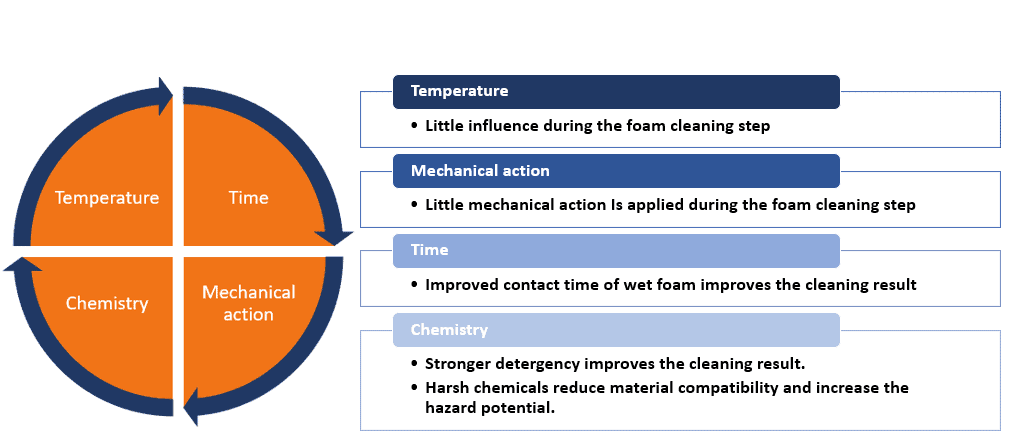

The Sinner Circle

The Sinner Circle for Cleaning Out of Place, consists of four main areas: Temperature, Time, Mechanics and Chemistry. Boosting one of these areas increases the overall cleaning result or allows the reduction of another. A deficit in one of these areas requires compensation in another.

1.) Temperature

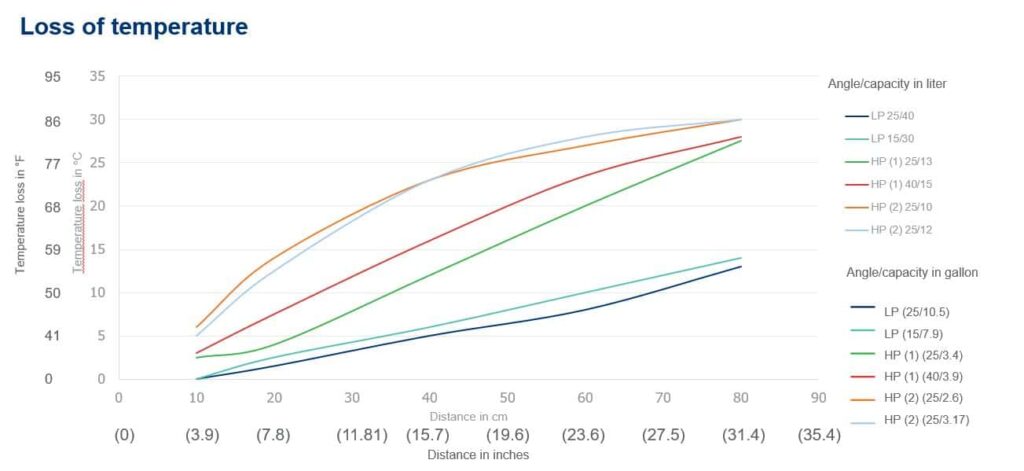

Temperature impacts the ability to melt and liquefy fats and other soils commonly found in the food and beverage industry. A big temperatures loss will significantly increase rinsing time and decrease productivity of rinsing operation – not just the pre-rinse phase as tested below, but also intermediate and post rinse phases.To see the overall efficiency of the pre-rinse phase, tests were done in a room with a temperature of 23 ̊C (+/-2 ̊C) / 73.4°F (+/- 28°F), and with a water temperature of 61 ̊C/141°F. The measurement was made by attaching temperature sensor at the end of nozzles as well as on the surface. As distance increases it is important to be able to preserve the temperature in the water.

| Loss of Temperature Test results | The low-pressure system clearly showed the best results. At a 50cm /19.6 inches distance, which is the most common working distance in real life situations, the low pressure system showed a temperature loss of just 6 ℃/42.8°F. This is the equivalent to just 9,9% energy loss. The system with the highest working pressure showed a temperature loss of 27 ℃/80.6°F, this is equivalent to a staggering 44,3% energy loss. What makes this possible: When a small amount of water is being pushed out at a high pressure it creates small water droplets that cools down rapidly when entering the atmosphere. In the opposite direction the low pressure system sends larger droplets into the atmosphere at a lower velocity making the cooling process slower. |

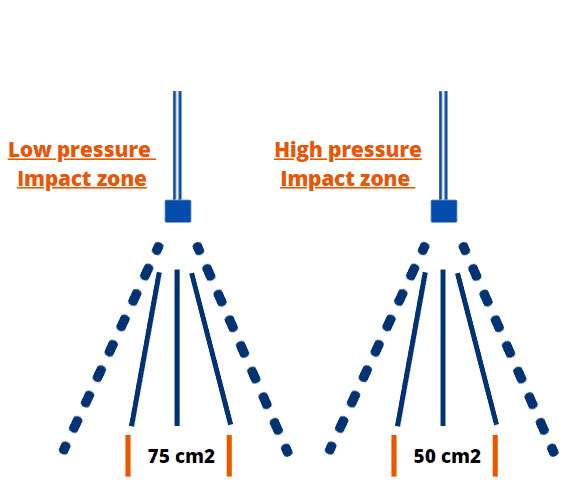

2.) Impact

The impact of the rinse pressure indicates the systems ability to remove soil from the surface. This helps determine the working efficiency of the system and the size of the area being rinsed. the following tests were made at several distance.

| Impact Test Results | The low pressure system with the 25/40 (25/10.6) nozzle had the larges rinsing area and covered an impressive 75cm2 on the surface at 50cm/ 19.6 inches rinsing distance. the width of the rinse fan was approx. 25 cm/ 9.8 inches at this rinsing distance. Each system was tested at the same distances, the low pressure 25/40 (25/10.6) nozzle has the highest impact in the middle 50% of the rise fan. this gives a local high pressure, which increases the cleaning efficiency of the low pressure system. What makes this possible: This answer has already been given- the physics behind this are the same as the one applied to preservation of temperature. If you have a high pressure washer at home to wash you car or patio, you may have noticed that at 50cm/19.6 inches from the nozzle you will find only vapor-size droplets, which provides little mechanical impact. In the opposite direction the low pressure system will provide a nice “burning” feeling in your finger. *Disclaimer* Please do not try this in real life- take our word for it! |

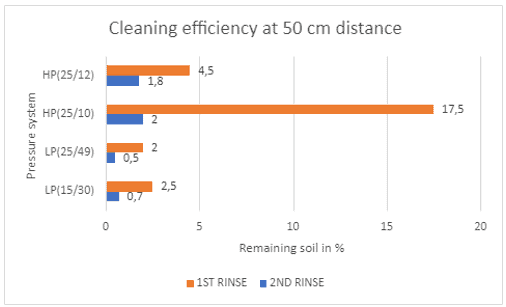

3.) Cleaning Efficiency

The cleaning efficiency is based off the cleaning equipment’s ability to remove soil from a surface. To test the cleaning efficiency for the three pressure systems a test was made by covering stainless steel plates in pork fat. The quantity of the fat was determined by GEL-tape and BM Dust Detector. The plates were first held in a room at ambient temperature for 16-18 hours. The test plates were moved two times back and forth underneath the rinse fan at a distance of 50 cm/19.6 inches. The water temperature at the nozzle was 59 ̊ C (+/-3 ̊ C) / 138°F (+/-26°F).

| Cleaning Efficiency Test Results | Low pressure cleaning has the best soil removal. The first rinse, (using low pressure), still has a more efficient clean than the 2nd rinse (using either of high pressure systems). What makes this possible: This is possible due to the preservation of temperature in the water over longer distances in combination with the higher mechanical impact in the rinse fan. Coming back to the Sinner Circle we are boosting the Temperature and Mechanics, which in real life would allow you to clean faster and thereby reduce the Time used for cleaning. |

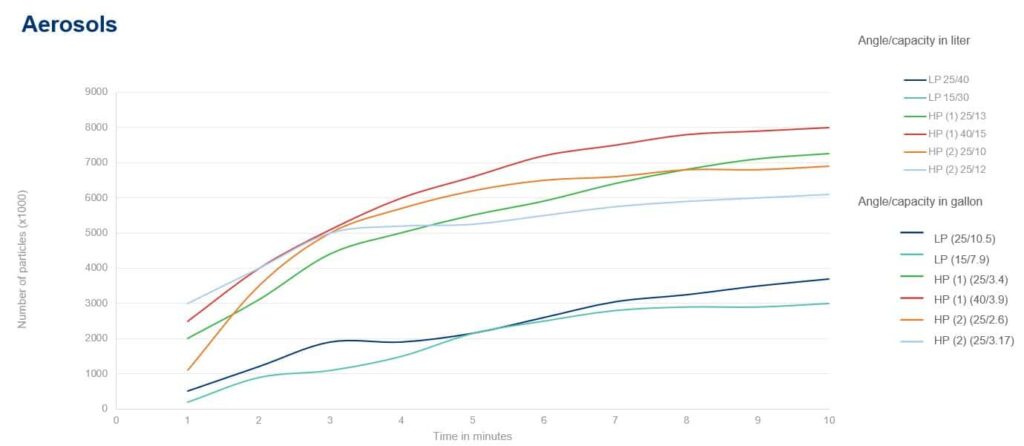

4.) Aerosols

Aerosols carry soil and bacteria, the presence of aerosols can re-contaminate an already cleaned surface. A system that spreads less aerosols are therefore more efficient.

Tests were made using a particle filter with cold water (16 ̊C/60°F) and the distance was 50 cm/19.6 inches from nozzle to surface. The measurement instrument was placed 5 meters/ 16 feet from the cleaning spot and placed 90 cm/ 35.4 inches above the floor.

| Aerosols Test Results | High pressure systems contributed to 2x more particles compared to the low pressure systems. Lower water pressure produces less aerosols because of the bigger droplets, which results in a decrease of post cleaning contamination. What makes this possible: The small droplets generated from the high pressure system are lighter thus travels further and higher, while also being in the air longer – gravitational force on these small droplets is very small. |

Conclusion:

While high pressure systems do use less water per minute, for the high pressure systems to clean at the same standard as the low pressure systems it would take far more time and increase water consumption overall. The low pressure system gave the best cleaning result within the food industry.

- Lowest temperature loss when increasing the distance to surfaced cleaned

- Largest cleaning area on surface

- Higher impact in central part of spray fan

- Best cleaning efficiency

- Lowest aerosols creation

Source: Norges Byggforskningsinstitut