There is a new sherif in town!

CAN WE INTRODUCE YOU TO “THERMOPLASTIC POLYMER?

-A gamechanger when it comes to coping with challenges in the Food & Beverage industry

Every day – equipment – used in the Food and Beverage industry – is exposed to harsh environment such as chemical attacks, high temperatures and hard water.

For decades Stainless Steel has been considered the most robust material, best suited for the food and beverage industry.

However – THERE IS A NEW SHERIF IN TOWN – Lets introduce you to “Thermoplastic Polymer”.!

This new material is introduced on several of Nilfisk FOODs Hybrid 7 components, primarily components in contact with water, detergent, and moisture – such as Block, injectors, chemical non-return valves, air-valve, and positioning plate.

It has been tested in our lab for two years and the results in the field have been outstanding.

WHATS IN IT FOR YOU?

Compared to stainless steel, the smooth surface of the Polymeric material prevents accumulation of scale and other deposits and is much more resistant to wear and tear.

In summary, polymeric components offer advantages in terms of production efficiency, longer equipment runtime before servicing and reduced receptivity to deposits like scale.

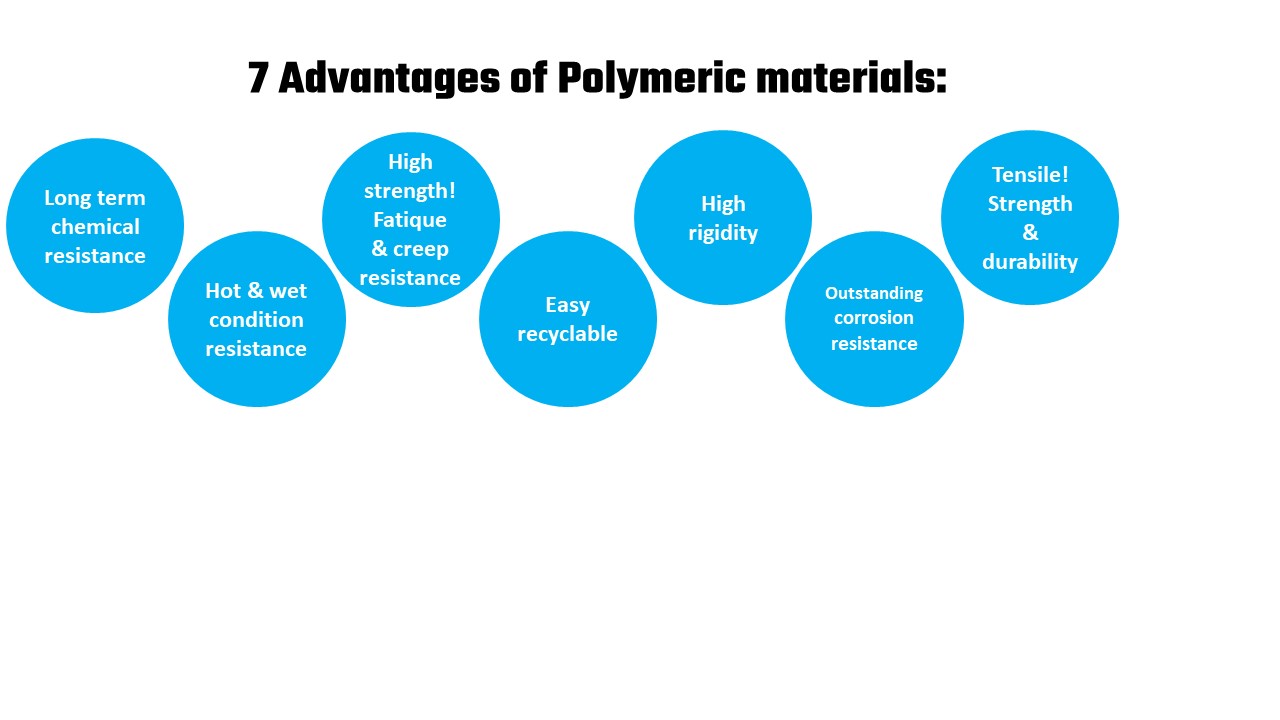

Compared to standard stainless-steel material the Polymeric material is superior when it comes to: functionality, strength, corrosion and recyclability.

For more information on why we now choose to use Polymeric – read our blog