What are the most effective methods for surface cleaning?

A food contact surface must be cleaned and sanitized – that is for sure. What are the most effective cleaning methods for surface cleaning?

This Blog will give you a full guide to all things related to Surface cleaning.

- What does it mean?

- Where is it used?

- What cleaning methods are used for surface cleaning?

- What is the correct order of cleaning contact surfaces?

- Cleaning equipment for smart cleaning

- Business cases showing surface cleaning

- What is the most effective cleaning method for your production facility?

Surface cleaning – What does it mean?

The surface cleaning process in food and beverage manufacturing plants involves cleaning and sanitizing of all surfaces, including floors, walls, tables, and other surfaces within the production area.

The term Surface cleaning is used in the cleaning and food processing industries but is often confusing because it can be named differently in different industries/countries/companies. The various terms are: COP, cleaning out of place, open plant cleaning, open works cleaning or surface cleaning.

Sometimes, the term surface cleaning is also referred to as Manual cleaning because the discharge hose used for cleaning is held manually by the cleaning personnel – See picture 1.

Surface cleaning – Where is it used?

Surface cleaning is a common method of cleaning in various industries like Food and beverage, Retail, Industrial kitchens, Life Sciences and Agricultural.

A food contact surface must be cleaned and sanitized. What cleaning methods are used for surface cleaning?

Four different cleaning methods/solutions are used for surface cleaning:

- Decentralized cleaning solution

- Centralized also called pre-diluted cleaning solution

- Tap water cleaning solution

- Air driven cleaning solution

There are several differences between these four methods, where the most important are:

- Water pressure used for cleaning

- Placement of detergents used for cleaning

- Sources that drive the equipment

a). Water pressure used for cleaning

In the decentralized and centralized methods, the water pressure can be adjusted from 5 bar up to 25 bar or even up to 40 bar (on the medium pressure range of equipment). The tap water method as the name indicate, works at the tap water pressure between 2-6 bar. The air driven system is only driven by air, therefore water pressure is not applicable for this method.

b). Placement of detergents

In the Decentralized, tap water and air driven cleaning solutions, the concentrated detergents are located inside of the production facilities in jerry cans or user packs (See pictures 1 and 2). In the Centralized method, the concentrated detergents are stored in a central room located outside of the production facilities (See picture 3).

c). Sources that drive the equipment

The Decentralized, centralized and tap water cleaning solutions are water driven, meaning that chemical pick up is caused by vacuum generated by water injected into the system. The Air driven system is purely air driven as the name indicates, meaning that air is injected into the system and pics up the detergent.

What is the correct order for cleaning food contact surfaces?

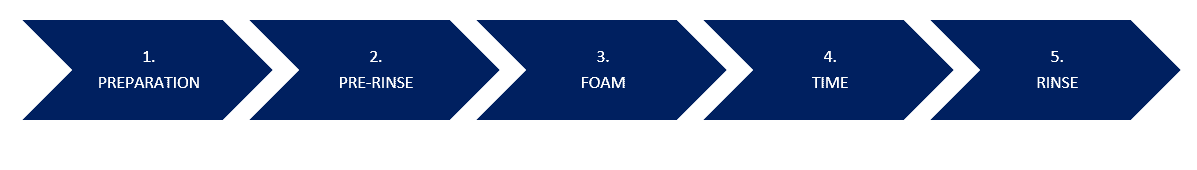

Complete surface cleaning process to achieve maximum hygiene results and food safety consists of ten steps shown in figure 1:

The cleaning process starts by preparing the area to be cleaned. Remove all the big food remains by hand, wet all surfaces (PRE-RINSE) and apply FOAM detergent. Let the detergents do the cleaning job for some TIME. RINSE the detergents from top to bottom. To check the cleaning results conduct the ATP SWAB TEST.

DISINFECT all food-contact surfaces in order to remove all harmful germs and reduce the growth of viruses, fungi, and other harmful bacteria. After some TIME, RINSE the detergent with clean water. At the end (POST PROCESSING) always remember to flush the cleaning equipment with clean water by replacing the detergent with water. The aim is to flush away the detergents from suction lines, injectors and non-return valves to prolong the service lifetime of the equipment and accessories. See Nilfisk FOOD’s How to use videos showing the operation procedure on cleaning and disinfecting equipment.

See video developed by one of our partners Ecolab showing the complete cleaning and disinfection process of surfaces in the food and beverage production facilities: https://youtu.be/3kDfJr1eouM

Cleaning equipment for smart cleaning

Nilfisk FOOD offer a full range of cleaning equipment for smart cleaning of surfaces in the food and beverage, Retail, Institutional, Life Sciences and Agricultural industries. We are the pioneer of the low-pressure foam cleaning technology and trendsetters within the world of industrial hygiene, specialized in optimizing cleaning processes and food safety around the globe. Thanks to our patented technologies we contribute to sustainable efforts aiming to protect the world’s most valuable resources and food safety of every production facility.

Review Business cases where Nilfisk FOOD’s equipment is used for surface cleaning:

- Food & Beverage – Sofrimar business case from the Fish industry

- Retail – Griff Whiteout unit used at Supermarket chain Costco

- Institutional market – Nommo tap used at industrial kitchens

Do you wonder what is the most effective cleaning method for your production facility?

There are many different factors to be taken into consideration when selecting the right cleaning method to clean surfaces. Some of them are:

- kind of dirt to be cleaned,

- size of your production facilities,

- water flow in your production facilities,

- access to external air,

- number of cleaning personnel cleaning at the same time,

- safety rules at your facilities,

- chemical handling rules

- budget and many other factors.

Book a 30-minute, free of charge consultancy session with our experts so we can discuss your requirements and jointly decide what type of equipment will work best for you.