At Nilfisk FOOD we take pride in being a pioneer and trendsetter within the world of industrial hygiene. Therefore, we are proud to introduce a new cutting-edge technology – the Hybrid 7 – to help food and beverage producers be more productive and competitive.

Hybrid 7 – THE NEW NORM of foam cleaning

The new normal calls for the new norm.

The world has changed. Increasing energy prices, water scarcity and shortage of labour is the new normal – and combined with future trends it calls for THE NEW NORM: Hybrid 7.

There is no doing business as usual in the food and beverage industry. Consumer behavior and attitudes have shifted towards food safety and sustainability. Hygiene is important because people want certainty that the food they eat and beverages they drink are safe and contamination-free. Innovative producers advance into the world of connectivity. Connecting equipment and factories around the world to create intelligent factories that ensure the highest efficiency, flexibility, quality, and sustainability. THE NEW NORM is the first step of the way.

Innovation Built on 7 Core Components

Nilfisk FOOD has spent years developing and testing this new technology based on the success and outstanding performance of the Hybrid line. Now it is finally here: The Hybrid 7.

Hybrid 7 is built on 7 core components, grouped into three main categories: Electronics, Software, and Mechanics. Each component delivers value on its own, but when connected and when connected to internet it enables digitalization of the cleaning industry.

Electronics

Electronics Inverter

Display

Multicontroller

Software

Hybrid 7 Software

NAVIGATOR

Mobile APP/Commander

Mechanics

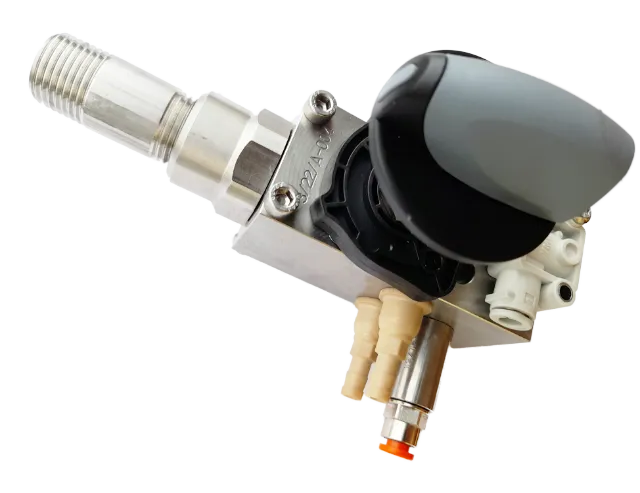

Foam block

Connectivity

Hybrid 7 connects data to minimize costs and make cleaning more efficient.

Imagine if you could monitor the temperature of water used for cleaning and get a notification when it’s too hot or too cold? Or get information about detergents or energy consumptions?

Connected to Wi-Fi or Bluetooth, Hybrid 7 creates data in real time, which enables a data driven decision making process and transparent reporting on sustainability goals and makes it possible to prevent critical issues before they unfold and minimize costs.

It’s all possible thanks to our technological advancement of the Hybrid 7’s electronical components such as the inverter, multicontroller, and display.

Optimized food and beverage

Hybrid 7 is optimized to solve typical challenges in the food and beverage industry.

All standard equipment available on the market run on Standard Inverters and use stainless steel components, but the Hybrid 7 takes the selection of components to the next level.

The Hybrid 7 inverter is 100% optimized to collect the needed information to reduce scaling on injectors and chemical non return valves in hard water areas and optimize components for corrosion when being in contact with chemicals.

The automated range has up to 100 cleaning steps and a new mobile app to satisfy the needs of even the most complex production facilities.

Modularity

By embracing modularity, we are revolutionizing our methodology to customize solutions, maximize performance, improve energy efficiency, and minimize waste.

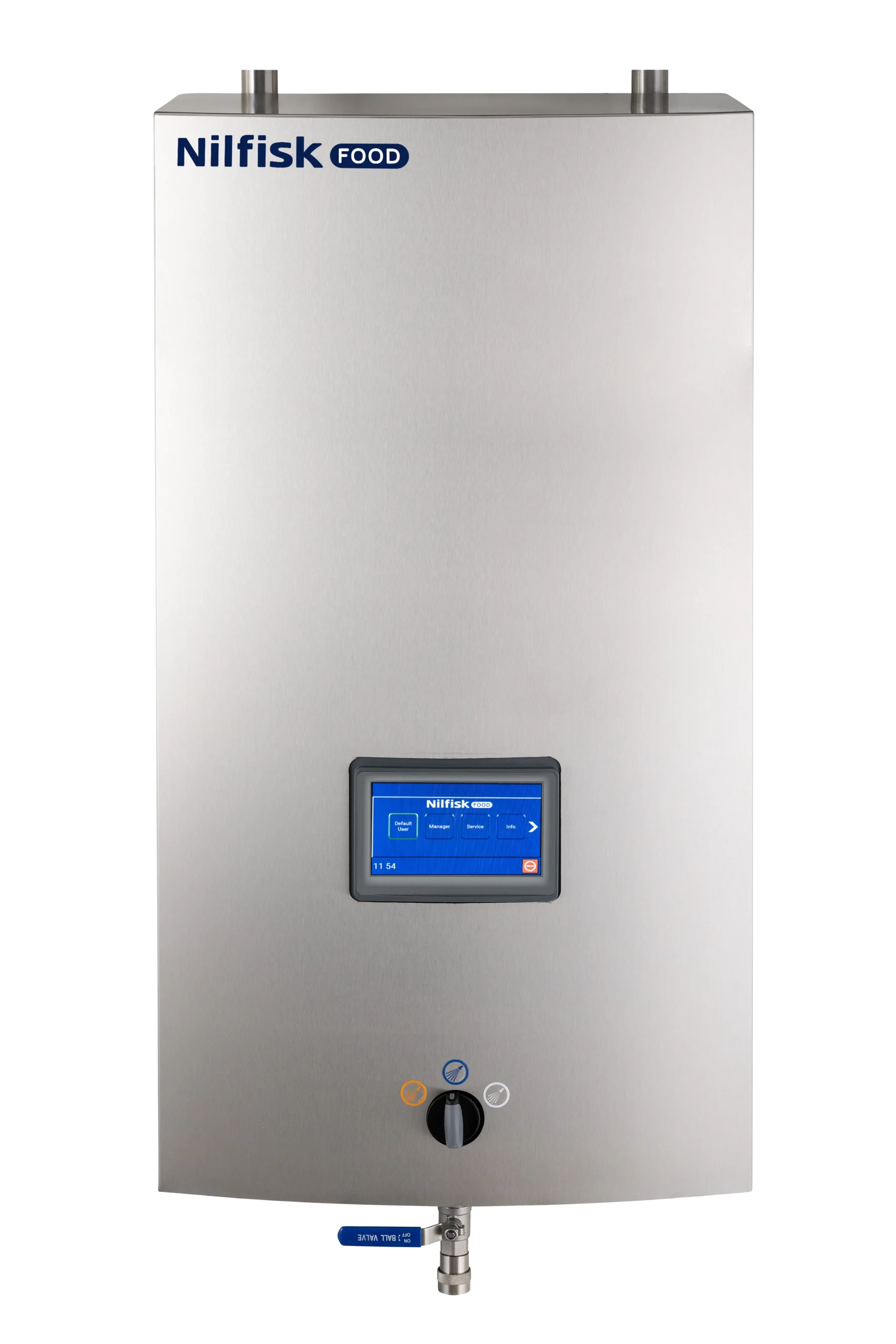

Modularity refers to combining distinct modules in various configurations, like stacking blocks to create different structures. We are introducing one platform of components (One Inverter, One multicontroller, and One block) across all Nilfisk FOOD portfolio (Mainstations, Boosters, Satellites, Pre-diluted equipment).

With the new Hybrid 7 inverter, we can run one worldwide model/voltage 380 to 528 Vac 50/60Hz. Modules can be easily updated and upgraded. Optimized module configurations reduce waste and resource consumption.

It simplifies service, decrease downtime, and decrease costs, all ensuring high customer satisfaction.

Remote Support

Hybrid 7 offers remote support minimizing your equipment downtime.

Cleaning is critical in the food and beverage industry, where downtime is not an option.

The Hybrid 7 comes with a remote support function allowing technicians to connect directly to your equipment. This makes it possible for them to help you troubleshoot and solve the problem in no time, so your equipment doesn’t have to be out of commission.

The Nilfisk IoT system is based on three subsystems:

- GUI Machine Interface

- Mobile app

For easy monitoring of all connected units

- Web App

Navigator web program enabling technicians to access remote connectivity and service of the unit.

Incl. the feature the Commander web program for monitoring and analyzing machine and cleaning parameters.

Sustainability

At Nilfisk FOOD we are committed to helping our distributors and end customers achieve cost effective and sustainable cleaning while improving environment impact.

Awareness and demand for sustainable cleaning is on the rise, and sustainability is becoming a key driver and qualifier for customers choosing or reassessing their cleaning equipment. Producers see the need and opportunity for sustainable cleaning.

Imagine achieving the best technically possible cleaning and hygienic results in your production facilities, using approx. 47% less water and 46% less detergent. All this is done 55% faster compared to cleaning using standard equipment available in the market, so you also can extend your uptime.

Moreover, the new Hybrid 7 inverter allows to save approx. 70% of energy, when the equipment is in standby mode.

For more overall info on how Nilfisk are committed to sustainability read here.

Guided service

By embracing guided service, we are guiding our distributors step by step through the process of servicing the Nilfisk FOOD equipment, with a purpose to maximize performance, minimize downtime and minimize cost.

With the guided error reading log that explains the errors and displays remedies actions to solve it, it is no longer necessary to download the error reading log to find out the type of error.

By embracing the real time surveillance, thanks to our new Hybrid 7 software technology, technicians will get the possibility to directly connect to the equipment, and help solve the problem, with great benefits both for our distributors and the end customers.

The guided service help to minimize resources needed to solve problems and maximize value for the end customers.

Savings

Legal regulations regarding Greenhouse Gas Emissions, water scarcity, increasing energy prices and shortage of labour are the new normal.

By introducing remote support, guided service, sustainability, modularity and by optimizing components specifically to satisfy needs of the food and beverage industry we revolutionize the cleaning industry. We enable the food and beverage producers to make significant savings when cleaning, while achieving the same, or even better level of cleaning efficiency, supporting sustainability, and maximizing production uptime.

With the Hybrid 7 you save the following:

- Water

Sustainabiltiy

- Detergent

Sustainability

- Energy

Sustainability

- Service time

Remote support, Guided service, Modularity, Optimized F&B

- Service expenses

Remote support, Guided service, Modularity

- Production downtime

Remote support, Guided service, Modularity

- Spare part expenses

Modularity, Optimized F&B

Hybrid 7 equipment range

Who we are?

Nilfisk FOOD challenge and define the future of hygienic cleaning of surfaces.

We are the pioneers of the low-pressure foam cleaning technology used for surface cleaning, and trendsetters within the world of industrial hygiene, specialized in optimizing cleaning processes and food safety around the globe.

Contact us

+45 72 182 000

info@nilfiskfood.com