Water pressure and water supply

Make sure that they have sufficient water supply available:

a. The boosters and mainstations require a 30 psi dynamic inlet pressure. Not 30 psi against a closed ball valve, but 30 psi when the unit(s) is in operation and using water.

b. The water volume available shall correspond to the number of simultaneous users +10%

Example

Customer wants a system for 6 simultaneous users, and they shall therefore supply minimum:

– 2 bar/ 30 psi dynamic inlet pressure

– 6 x 30lpm= 180 lpm + 10%x180 lpm = 198 lpm /6x 8 gpm = 48 gpm + 10%x48 gpm = 53 gpm

Hot water temperature?

Hot & cold water mix?

Piping pressure?

Check the water pressure that the existing piping can handle. Often it is only up to 15 bar/200 psi, and our equipment run on 25 bar/362 psi.

If the existing piping can handle up to 15 bar/ 200 psi, the cheapest option is to go with a mainstation(s) and satellites setup, because here we will connect to water supply in the production area and branch out with new piping from mainstation(s) to satellites.

If the piping can handle up to 25bar/362 psi, the cheapest option is to utilize existing piping and just connect a booster (s).

Power supply

The cleaning equipment require sufficient power supply

3 phases 480V/60Hz, and kW that varies depending on number of users from 6kW for 4 users up to 44kW for 32 users

Since these units are with frequency inverter the ELCB must be of type B, and have sufficient A (Amps) as well.

Drop stations lpm/gpm?

Each drop station use 30 lpm/8 gpm.

Compressed air capacity?

Each Mainstation and satellite/drop station (that has an outlet for cleaning) requires an air pressure of min. 6 bar/87 psi to make foam

b. It is important that the compressor has sufficient volume as well so that we ensure enough air to generate nice thick foam. Each outlet requires 5,3 cfm.

Example:

A customer wants a system for 6 simultaneous users, and they shall therefore supply min.;

– 6 bar/ 87 psi air pressure

– 6x 5,3 cfm = 32 cfm

Hot water booster pump supplied by holding tank?

Dimensions of individual rooms?

Order guide for Ecolab Europe

Order guide for Ecolab USA

Each user, need a satellite/drop station/working station to do the cleaning job.

The amount of the satellites to be ordered, depends on how many simultaneous users work at the customer.

First you need to select a unit with pump (Mainstation or Booster) that supply pressurized water to the satellites/drop stations, and then select the satellites/drop stations (keep on reading to find out why).

The number of the cleaning equipment (BF4, BF8, BW7…) indicate the MAXIMIM number of users that clean at the same time (simultaneous users) on this equipment.

If more users will clean than the allowed number, there won’t be enough water volume and water pressure. Thanks to the dry run protection mounted on our Boosters and Mainstations, the pump will stop to protect the unit from burning down, but the cleaning process and results will not be optimal.

Example: If you need equipment for 4 simultaneous users you can order one of the following:

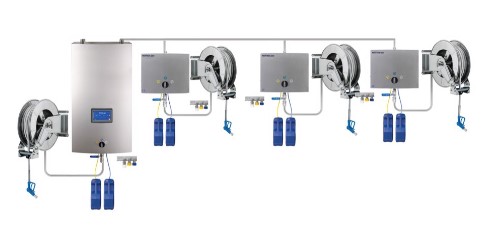

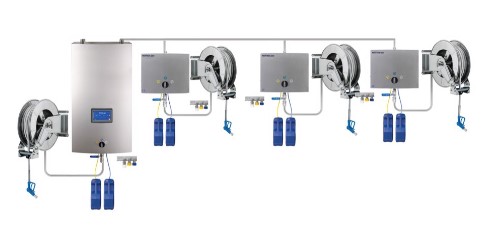

EITHER 1 x Mainstation + 3 satellites/drop stations (Mainstation functions as drop station itself, because it has a built-in block, so you save one drop station on the installation)

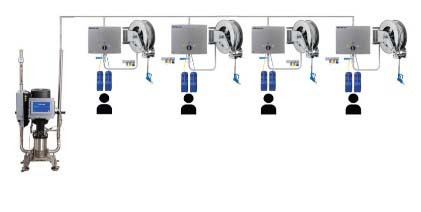

OR 1 x BF4/BW4 + 4 satellites/drop stations (Booster only functions as a pump station, therefore 4 drop stations must be ordered for 4 simultaneous users).

Important to consider:

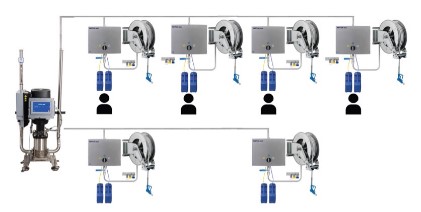

It is allowed to connect additional drop stations (that can be used for cleaning in other zones at another time), but the max. number of simultaneous users must be respected.

This is to secure enough water volume and pressure and the best cleaning results.

BF4 + 4 drop stations (for 4 simultaneous users) + 2 additional drop stations for cleaning in other zones at another time (or with different chemicals)

Each mainstation and satellites/drop stations need to be equipped with accessories.

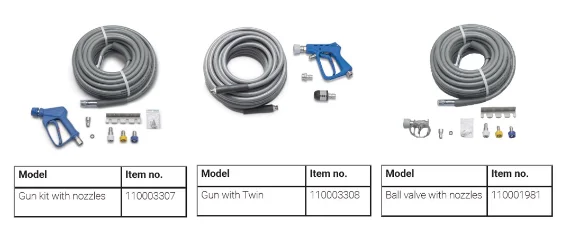

Choose between three accessories kits

What they have in common?

15m/80ft Foodgrade Purflex hose,

2 chemical suction hoses 2.5 m /8ft each (blue and yellow),

Male quick connector with o-ring

What is different?

Gun or ball valve. Gun is more ergonomic to work with, ball valve is an economic solution.

|

Gun |

Ball valve |

|

|

|

Nozzles

Gun and Ball valve kit include three color coded nozzles that match the stickers of the cleaning steps on the equipment – see video

|

|

Blue – Patented Tornado nozzle used for rinsing White – nozzle used for foaming (it has a special mesh that support the foam creation) Yellow – nozzle used for spray disinfection (if you want to foam disinfect use the white nozzle). |

|

|

Twin kit has a Twin nozzle used for all three cleaning functions (rinse, foam, disinfect). You simply pull the nozzle to change between foaming and rinsing (or spraying desinfection). Some users say that using the Twin nozzle save time on changing between the nozzles, and prevent from loosing the nozzles. |

Nozzle sizes

Blue rinse nozzle – Standard size in the kits is 15/30 made from Stainless Steel.

15 indicates the spread angle in degrees (15°), and the second number indicates the amount of water (30 lpm/ 8 gpm).

If you need more water for cleaning, purchase another nozzle 15/40 – the spread angle is the same, but the water volume is bigger (40 lpm/10.5 gpm)

White foam nozzle – Standard size in the kits is 50/150 made from Stainless Steel.

50 indicates the spread angle in degrees (50°), and the second number indicate the amount of foam (150 lpm/ 40 gpm).

If you would like to experiment with foam, we have another size of foam nozzle available: 50/200 (50° spread angle, 200lpm/53 gpm).

Yellow disinfection nozzle is only available in one standard size 40/30 made from stainless steel (spread angle 40°, and 30 lpm/8 gpm).

All quick couplings (between mainstation and hose, hose and gun) have a pressure lock couplings for maximum user safety – see video.